Good Quality Linear Stepper Motor – CNC Turning types stainless steel / aluminum flexible coupling for motor – Bobet

Good Quality Linear Stepper Motor – CNC Turning types stainless steel / aluminum flexible coupling for motor – Bobet Detail:

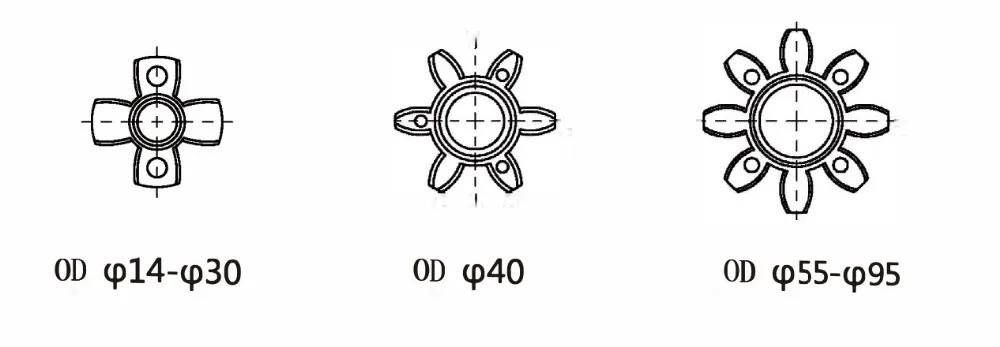

Curved Jaw Couplings

The Curved Jaw couplings can be utilized in many applications and serve as an all-purpose coupling. The basic design of the Curved Jaw allows for al higher torque capacity in a compact design. The curved tooth has a greater contact area which gives it the high torque capacity, and reduces edge pressure. It will accommodate axial, radial and angular shaft misalignments.

The hubs are produced from a variety of materials including: aluminum, gray ,iron, steel, sintered steel, and stainless steel. The spider elements are available in various durometer options in Urethane & Hytrel. The spiders can perform under normal duty cycle conditions to heavy duty cycles which include shock loading and can minimize torsional vibrations in the system.

|

Model

|

Bore size (mm)

|

RatedTorque (N.m)

|

MaxTorque(N.m)

|

Max speed

|

Outer Diameter (mm)

|

Length (mm)

|

Bore Tolerance (mm)

|

|

HS -TCN-14C

|

3~7

|

0.7

|

1.4

|

45000

|

14

|

22

|

+0.6~0

|

|

HS-TCN-20C-R

|

4~11

|

1.8

|

3.6

|

31000

|

20

|

30

|

+0.8~0

|

|

HS-TCN-30C-R

|

6~16

|

4

|

8

|

21000

|

30

|

35

|

+1.0~0

|

|

HS-TCN-40C-R

|

8~28

|

4.9

|

9.8

|

15000

|

40

|

66

|

+1.2~0

|

|

HS-TCN-55C-R

|

9.5~32

|

17

|

34

|

11000

|

55

|

78

|

+1.4~0

|

|

HS-TCN-65C-R

|

12.7~38.1

|

46

|

92

|

9000

|

65

|

90

|

+1.5~0

|

Spider Characteristics

The curved jaw coupling includes two metal hubs and an elastomeric “spider” element. The spiders are available in

different hardness durometers, each easily identified by its color.

|

Hardness

|

Color

|

Material

|

Temperature Range

|

Applications

|

|

80 Shore A

|

Blue

|

Polyurethane

|

-50 ~+80 .C

|

Excellent damping

|

|

92 Shore A

|

Yellow

|

Polyurethane

|

-40~+90 .C

|

Moderate damping, general applications

|

|

98 Shore A

|

Red

|

Polyurethane

|

-30 ~+90 .C

|

High torque applications

|

|

64 Shore D

|

Green

|

Polyurethane

|

-50 ~+120 .C

|

Higher torque, high temperature

|

Coupling measure information

|

A

|

L

|

W

|

B

|

C

|

F

|

G

|

M

|

|

14

|

7

|

22

|

6

|

1

|

3.5

|

4/5

|

M2/M1.6

|

|

20

|

10

|

30

|

8

|

1

|

5

|

6.5/7.5

|

M2.5/M2

|

|

30

|

11

|

35

|

10

|

1.5

|

8.5

|

10/11

|

M4/M3

|

|

A

|

L

|

W

|

B

|

C

|

F

|

G

|

M

|

|

40

|

25

|

66

|

12

|

2

|

8.5

|

14/15.75

|

M5/M4

|

|

A

|

L

|

W

|

B

|

C

|

F

|

G

|

M

|

|

55

|

30

|

78

|

14

|

2

|

10.5

|

20/21

|

M6/M5

|

|

60

|

35

|

90

|

15

|

2.5

|

13

|

24/25

|

M8/M6

|

Product detail pictures:

Related Product Guide:

Cooperation

We love an incredibly fantastic standing amid our consumers for our superb item high quality, aggressive rate and also the finest assistance for Good Quality Linear Stepper Motor – CNC Turning types stainless steel / aluminum flexible coupling for motor – Bobet , The product will supply to all over the world, such as: Philippines, Iran, Houston, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you always.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.