Good Quality Linear Stepper Motor – CNC Turning types stainless steel / aluminum flexible coupling for motor – Bobet

Good Quality Linear Stepper Motor – CNC Turning types stainless steel / aluminum flexible coupling for motor – Bobet Detail:

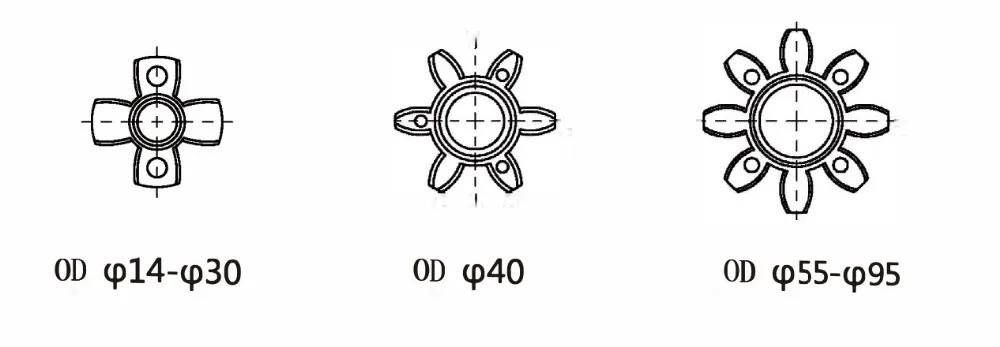

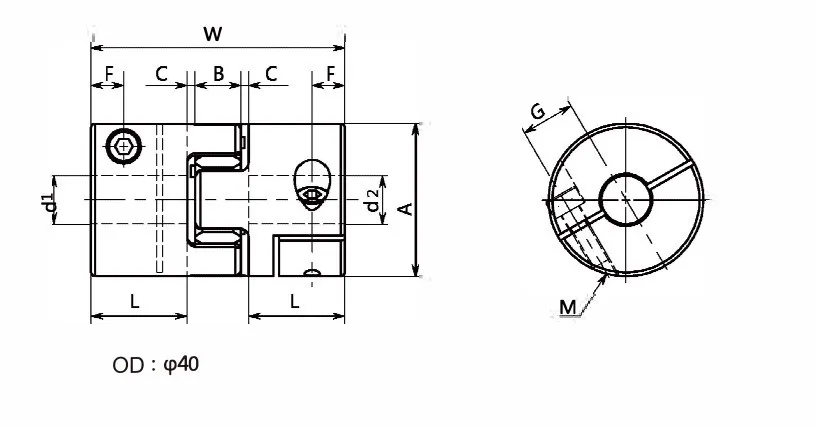

Curved Jaw Couplings

The Curved Jaw couplings can be utilized in many applications and serve as an all-purpose coupling. The basic design of the Curved Jaw allows for al higher torque capacity in a compact design. The curved tooth has a greater contact area which gives it the high torque capacity, and reduces edge pressure. It will accommodate axial, radial and angular shaft misalignments.

The hubs are produced from a variety of materials including: aluminum, gray ,iron, steel, sintered steel, and stainless steel. The spider elements are available in various durometer options in Urethane & Hytrel. The spiders can perform under normal duty cycle conditions to heavy duty cycles which include shock loading and can minimize torsional vibrations in the system.

|

Model

|

Bore size (mm)

|

RatedTorque (N.m)

|

MaxTorque(N.m)

|

Max speed

|

Outer Diameter (mm)

|

Length (mm)

|

Bore Tolerance (mm)

|

|

HS -TCN-14C

|

3~7

|

0.7

|

1.4

|

45000

|

14

|

22

|

+0.6~0

|

|

HS-TCN-20C-R

|

4~11

|

1.8

|

3.6

|

31000

|

20

|

30

|

+0.8~0

|

|

HS-TCN-30C-R

|

6~16

|

4

|

8

|

21000

|

30

|

35

|

+1.0~0

|

|

HS-TCN-40C-R

|

8~28

|

4.9

|

9.8

|

15000

|

40

|

66

|

+1.2~0

|

|

HS-TCN-55C-R

|

9.5~32

|

17

|

34

|

11000

|

55

|

78

|

+1.4~0

|

|

HS-TCN-65C-R

|

12.7~38.1

|

46

|

92

|

9000

|

65

|

90

|

+1.5~0

|

Spider Characteristics

The curved jaw coupling includes two metal hubs and an elastomeric “spider” element. The spiders are available in

different hardness durometers, each easily identified by its color.

|

Hardness

|

Color

|

Material

|

Temperature Range

|

Applications

|

|

80 Shore A

|

Blue

|

Polyurethane

|

-50 ~+80 .C

|

Excellent damping

|

|

92 Shore A

|

Yellow

|

Polyurethane

|

-40~+90 .C

|

Moderate damping, general applications

|

|

98 Shore A

|

Red

|

Polyurethane

|

-30 ~+90 .C

|

High torque applications

|

|

64 Shore D

|

Green

|

Polyurethane

|

-50 ~+120 .C

|

Higher torque, high temperature

|

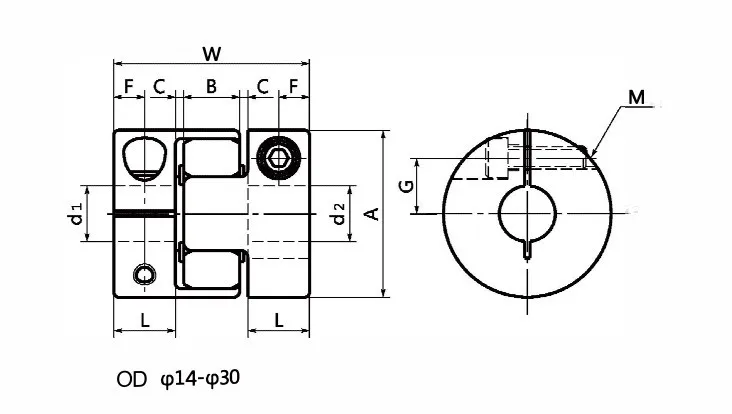

Coupling measure information

|

A

|

L

|

W

|

B

|

C

|

F

|

G

|

M

|

|

14

|

7

|

22

|

6

|

1

|

3.5

|

4/5

|

M2/M1.6

|

|

20

|

10

|

30

|

8

|

1

|

5

|

6.5/7.5

|

M2.5/M2

|

|

30

|

11

|

35

|

10

|

1.5

|

8.5

|

10/11

|

M4/M3

|

|

A

|

L

|

W

|

B

|

C

|

F

|

G

|

M

|

|

40

|

25

|

66

|

12

|

2

|

8.5

|

14/15.75

|

M5/M4

|

|

A

|

L

|

W

|

B

|

C

|

F

|

G

|

M

|

|

55

|

30

|

78

|

14

|

2

|

10.5

|

20/21

|

M6/M5

|

|

60

|

35

|

90

|

15

|

2.5

|

13

|

24/25

|

M8/M6

|

Product detail pictures:

Related Product Guide:

Cooperation

We have our own sales team, design team, technical team, QC team and package team. We have strict quality control procedures for each process. Also, all of our workers are experienced in printing field for Good Quality Linear Stepper Motor – CNC Turning types stainless steel / aluminum flexible coupling for motor – Bobet , The product will supply to all over the world, such as: Nairobi, Korea, European, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.