Manufacturer for Milling Motor Spindle - 5M-6-100A rotary axis with tailstock – Bobet

Manufacturer for Milling Motor Spindle - 5M-6-100A rotary axis with tailstock – Bobet Detail:

Chuck type: K11-100mm 3 jaw centering chuck

Center height: 65mm

Angle: 0.3°/ step

Output shaft diameter: 30mm

Hollow inner diameter: 22mm

Reducing ratio: 6:1

Stepper motor: 2-phase Nema23 3Amps 20kg.cm holding torque

Accessories: Set of Anti-claw and wrenches

Dimension: 210MM*168MM*115MM

Weight: 7.5KG

Tailstock

Center Height: 65mm

Stretch distance:50mm

Top tip: activity type

Axial locking wrench for tailstock

Net Weight:2.5kgs

The 4th and 5th Axis

Chuck type: K01-100mm 3 jaw chuck

Center height: 98mm

The 4th axis reducing ratio: 8:1

The 5th axis reducing ratio: 6:1

Working table size: 100x125mm

Stepper motor: 2-phase Nema23 3Amps 20kg.cm holding torque Size: 440x150x160mm

Weight: 12KG

Provide:

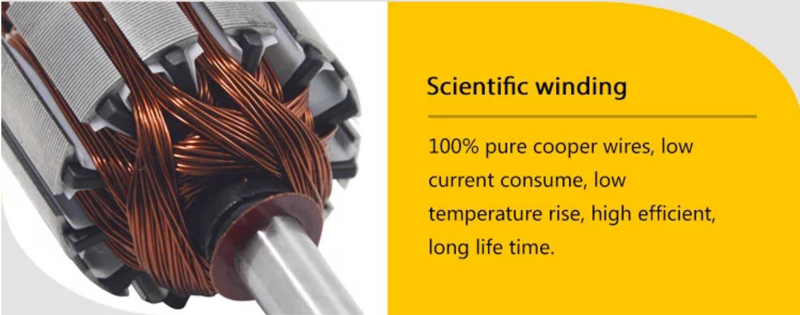

1.water cooling:300w,800w,1.2kw,1.5kw,2.2kw,3kw,4kw,3.2kw,4.5kw,5.5kw

2.air cooling: 800w,1.5kw,2.2kw.3.5kw,4.5kw,6kw,7.5kw,12kw

3.cooled by self: 400w

4.ATC spindle: cooled by water: 1.5kw,2.2kw,5.5kw,6kw,7.5kw

cooled by air: 8kw,9kw (same HSD)

5.sealing side spindle:350w,550w,700w,750w,1.1kw,1.8kw,2.2kw

We also have spindle motor matching inverter(VFD),water pump,bracket, collect , gripper etc.

If you need other kinds of parts, please don’t hesitate to contact us.

Product detail pictures:

Related Product Guide:

Cooperation

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Manufacturer for Milling Motor Spindle - 5M-6-100A rotary axis with tailstock – Bobet , The product will supply to all over the world, such as: Denmark, Moscow, United States, We'll initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.