Manufacturer for Stepper Motor Driver 0.9 Degree 1.8 Degree 3.75 Degree High Torque Stepper Motor With Driver Size 42mm Rated Current 0.4~2A For 3D Printer

Sticking to your principle of “Super Good quality, Satisfactory service” ,We are striving to get a fantastic business enterprise partner of you for Manufacturer for Stepper Motor Driver 0.9 Degree 1.8 Degree 3.75 Degree High Torque Stepper Motor With Driver Size 42mm Rated Current 0.4~2A For 3D Printer, We warmly welcome mates from all walks of life to hunt mutual cooperation and develop a more good and splendid tomorrow.

Sticking to your principle of “Super Good quality, Satisfactory service” ,We are striving to get a fantastic business enterprise partner of you for , As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, you should contact us. And It is our great pleasure if you like to have a personally meeting in our office.

M430D

Stepper Motor Driver Specification

Overview

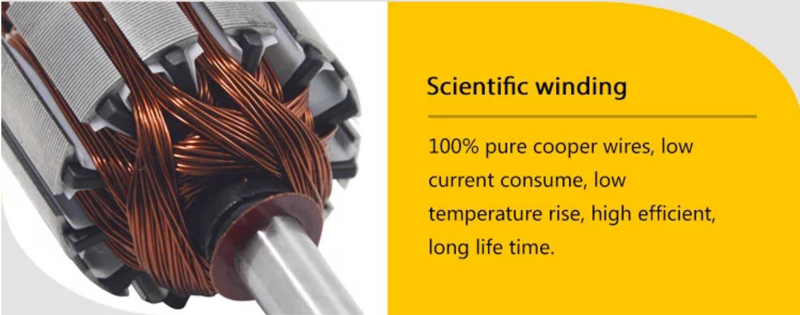

The M430D is a new generation microstep stepper motor driver. Due to the adoption of the advanced bipolar constant-current chopper driver technology, it shows stable operation, provides excellent high torque. Moreover, it significantly reduces the noises and vibration of the operating motor. The M430D has the feature of low-noise, low-vibration and low-heating. The M430D is DC18-40V power supply. It applies to 2-phase hybrid stepper motor under 3.0A current. The M430D has seven kinds of microsteps. The maximum step number is 12800 steps/rev (microstep is 1/64). The peak operating current ranges from 0.9A to 3.0A., and the output current has 8 stalls. The M430D has automatic semi-flow, motor misconnected protection functions and so on.

Applications

It can be applied in a variety of small scale automation equipment and instruments, such as labeling machine, cutting machine, packing machine, drawing machine, engraving machine, CNC machine and so on. It always performs well when it is used in equipment which requires for low-vibration, low-noise, high-precision and high-velocity.

Microstep selection

|

Pulse/Rev |

SW1 |

SW2 |

SW3 |

|

200 |

off |

off |

off |

|

400 |

on |

off |

off |

|

800 |

off |

on |

off |

|

1600 |

on |

on |

off |

|

3200 |

off |

off |

on |

|

6400 |

on |

off |

on |

|

12800 |

off |

on |

on |

Current selection

|

Peak |

RMS |

SW5 |

SW6 |

SW7 |

|

0.9A |

0.65A |

on |

on |

on |

|

1.2A |

0.86A |

on |

on |

off |

|

1.5A |

1.10A |

on |

off |

on |

|

1.8A |

1.28A |

on |

off |

off |

|

2.1A |

1.50A |

off |

on |

on |

|

2.4A |

1.72A |

off |

on |

off |

|

2.7A |

1.93A |

off |

off |

on |

|

3.0A |

2.14A |

off |

off |

off |

Driver functions descriptions

|

Driver function |

Operating instructions |

|

Output current setting |

Users can set the driver output current by SW5-SW7 three switches.

The setting of the specific output current, please refer to the instructions of the driver panel figure. |

|

Microstep setting |

Users can set the driver Microstep by the SW1-SW3 three switches. The setting of the specific Microstep subdivision, please refer to the instructions of the driver panel figure. SW4 and SW8 is vacancy, they do not need to be adjusted. |

|

Signal interfaces |

PUL is the setting pulse input; DIR is the stepper motor direction input; OPTO is the power supply for signal port + 5V; ENA is the motor free input. |

|

Motor interfaces |

A+ and A- are connected to a phase winding of motor; B+ and B- are connected to another phase winding of motor. If you need to backward, one of the phase windings can be reversed. |

|

Power interfaces |

It uses DC power supply. Recommended operating voltage is 18VDC-40VDC, and power consumption should be greater than 100W. |

|

Installation instructions |

Driver dimensions:117×71×35mm, please refer to dimensions diagram. Please leave 10CM space for heat dissipation. During installation, it should be close to the metal cabinet for heat dissipation. |

Signal interface details:

The internal interface circuits of the driver are isolated by the opt coupler signals, R in the figure is an external current limiting resistor. The connection is differential. And it has a good anti-jamming performance.

common cathode connection

common anode connection

Control signal and external interface:

|

Signal amplitudes |

External current limiting resistor R |

|

5V |

Without R |

|

12V |

680Ω |

|

24V |

1.8KΩ |

Sticking to your principle of “Super Good quality, Satisfactory service” ,We are striving to get a fantastic business enterprise partner of you for Manufacturer for Stepper Motor Driver 0.9 Degree 1.8 Degree 3.75 Degree High Torque Stepper Motor With Driver Size 42mm Rated Current 0.4~2A For 3D Printer, We warmly welcome mates from all walks of life to hunt mutual cooperation and develop a more good and splendid tomorrow.

Manufacturer for , As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, you should contact us. And It is our great pleasure if you like to have a personally meeting in our office.