Synchronous Motor 24vac Supplier – M545D DC stepper motor driver 2 phase 1.5-4.5A step driver – Bobet

Synchronous Motor 24vac Supplier – M545D DC stepper motor driver 2 phase 1.5-4.5A step driver – Bobet Detail:

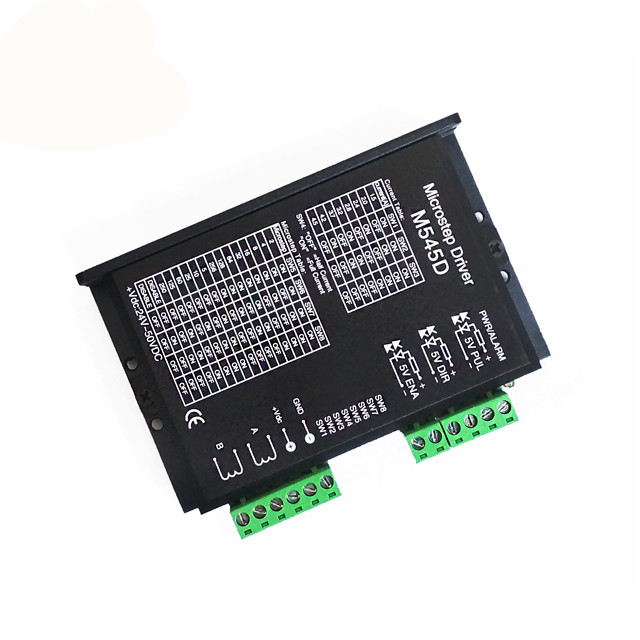

M545D

Stepper Motor Driver Specification

Overview

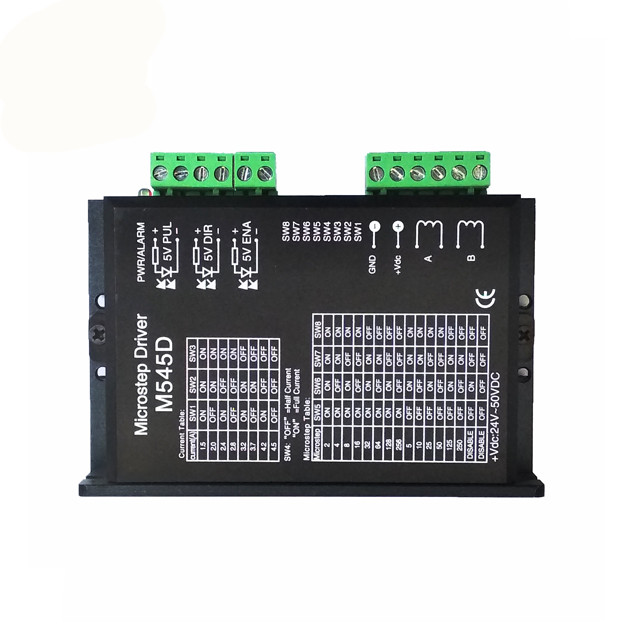

The M545D is a new generation microstep stepper motor driver. Due to the adoption of the advanced bipolar constant-current chopper driver technology, it shows stable operation, provides excellent high torque. Moreover, it significantly reduces the noises and vibration of the operating motor. The M545D has the feature of low-noise, low-vibration and low-heating. The M545D is DC24-50V power supply. It applies to 2-phase hybrid stepper motor under 4.5A current The M545D has 14l kinds of microsteps. The maximum step number is 51200 steps/rev (microstep is 1/256). The peak operating current ranges from 1.5A to 4.5A., and the output current has 8 stalls. The M545D has automatic semi-flow, motor misconnected,over-voltage, under-voltage, and over-current protection functions.

Applications

It can be applied in a variety of small scale automation equipment and instruments, such as labeling machine, cutting machine, packing machine, drawing machine, engraving machine, CNC machine and so on. It always performs well when it is used in equipment which requires for low-vibration, low-noise, high-precision and high-velocity.

Current selection

|

Peak |

RMS |

SW1 |

SW2 |

SW3 |

|

1.5A |

1.07A |

on |

on |

on |

|

2.0A |

1.43A |

off |

on |

on |

|

2.4A |

1.72A |

on |

off |

on |

|

2.8A |

2.00A |

off |

off |

on |

|

3.2A |

2.28A |

on |

on |

off |

|

3.7A |

2.64A |

off |

on |

off |

|

4.2A |

3.00A |

on |

off |

off |

|

4.5A |

3.21A |

off |

off |

off |

Microstep selection

|

Pulse/Rev |

SW5 |

SW6 |

SW7 |

SW8 |

|

400 |

on |

on |

on |

on |

|

800 |

on |

off |

on |

on |

|

1600 |

on |

on |

off |

on |

|

3200 |

on |

off |

off |

on |

|

6400 |

on |

on |

on |

off |

|

12800 |

on |

off |

on |

off |

|

25600 |

on |

on |

off |

off |

|

51200 |

on |

off |

off |

off |

|

1000 |

off |

on |

on |

on |

|

2000 |

off |

off |

on |

on |

|

5000 |

off |

on |

off |

on |

|

10000 |

off |

off |

off |

on |

|

25000 |

off |

on |

on |

off |

|

50000 |

off |

off |

on |

off |

Driver functions descriptions

|

Driver function |

Operating instructions |

|

Output current setting |

Users can set the driver output current by SW1-SW3 three switches.The setting of the specific output current, please refer to the instructions of the driver panel figure. |

| Microstep setting | Users can set the driver Microstep by the SW5-SW8 four switches. The setting of the specific Microstep subdivision, please refer to the instructions of the driver panel figure. |

|

Automatic half current function |

Users can set the driver half flow function by SW4. “OFF” indicates the quiescent current is set to half of the dynamic current, that is to say, 0.5 seconds after the cessation of the pulse, current reduce to about half automatically. “ON” indicates the quiescent current and the dynamic current are the same. User can set SW4 to ”OFF”, in order to reduce motor and driver heating and improve reliability. |

|

Signal interfaces |

PUL+ and PUL- are the positive and negative side of control pulse signal; DIR+ and DIR- are the positive and negative side of direction signal; ENA+ and ENA- are the positive and negative side of enable signal. |

|

Motor interfaces |

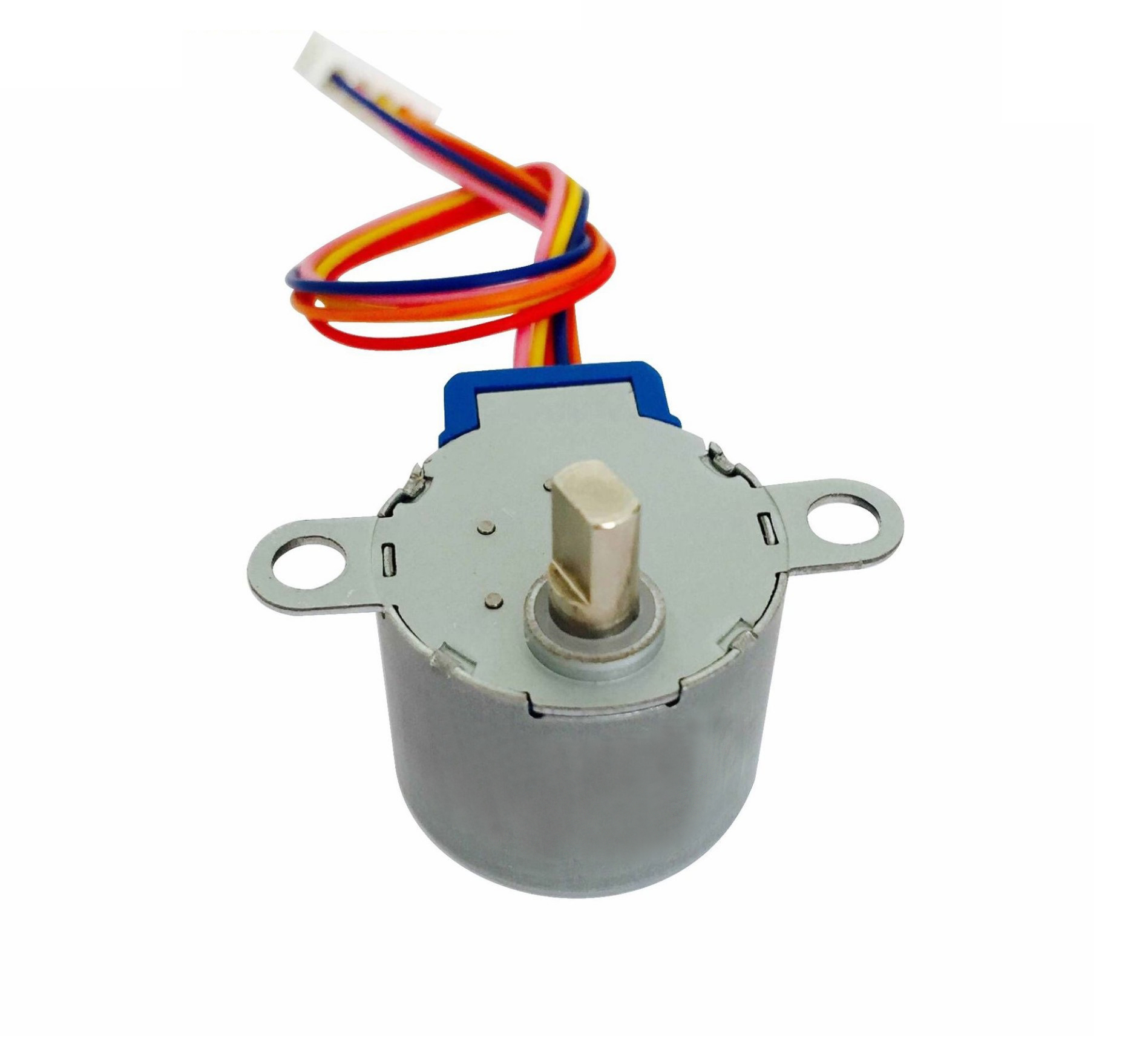

A+ and A- are connected to a phase winding of motor; B+ and B- are connected to another phase winding of motor. If you need to backward, one of the phase windings can be reversed. |

|

Power interfaces |

It uses DC power supply. Recommended operating voltage is 24VDC-50VDC, and power consumption should be greater than 100W. |

|

Indicator lights |

There are two indicator lights. Power indicator is green. When the driver power on, the green light will always be lit. Fault indicator is red, when there is over-voltage or over-current fault, the red light will always be lit; after the driver fault is cleared, if re-power the red light will be off. |

|

Installation instructions |

Driver dimensions:118×75×32mm, please refer to dimensions diagram. Please leave 10CM space for heat dissipation. During installation, it should be close to the metal cabinet for heat dissipation. |

Signal interface details:

The internal interface circuits of the driver are isolated by the opt coupler signals, R in the figure is an external current limiting resistor. The connection is differential. And it has a good anti-jamming performance.

common cathode connection

common anode connection

Control signal and external interface:

|

Signal amplitudes |

External current limiting resistor R |

|

5V |

Without R |

|

12V |

680Ω |

|

24V |

1.8KΩ |

Common indicator

|

Phenomenon |

Reason |

Solution |

|

The red indicator is on. |

1. A short circuit of motor wires. | Inspect or change wires |

| 2. The external voltage is over or low than the driver’s working voltage. | Adjust the voltage to a reasonable rang | |

| 3. Unknown reason | Return the goods |

Outline and installation size (unit:mm)

Contact us:

Lisa Chian/Sales Supervisor

Mobile/Wechat: 86-135 28805695

Mail: isales201@szbobet.com

Web: www.szbobet.com

Post Code: 518131

Add : Bld.L,Dongyi Industrial Park,Rd.Jinglongzhonghuan,Minzhi Street,

Longhua Area,Shenzhen City,Guangdong Province, China

Product detail pictures:

Related Product Guide:

Cooperation

We support our prospective buyers with ideal top quality merchandise and superior level provider. Becoming the specialist manufacturer in this sector, we have now attained abundant practical expertise in producing and managing for Synchronous Motor 24vac Supplier – M545D DC stepper motor driver 2 phase 1.5-4.5A step driver – Bobet , The product will supply to all over the world, such as: Moscow, Spain, Grenada, "Good quality and reasonable price" are our business principles. If you are interested in our products or have any questions, make sure you feel free to contact us. We hope to establish cooperative relationships with you in the near future.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.